Wet Process PU Resin

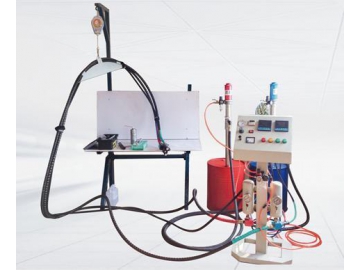

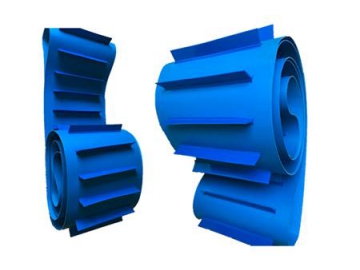

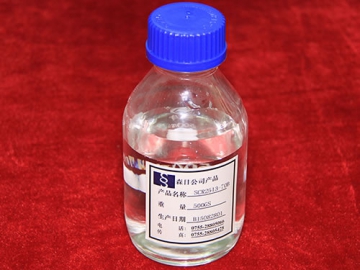

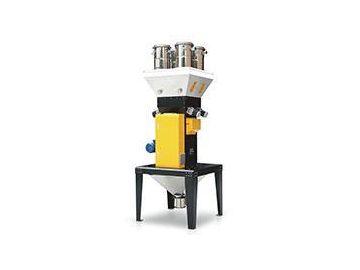

Wet process PU resin is produced by adding DMF solvents and other additives to the raw resin. The obtained mixture is then deaerated by a vacuum machine and dipped or coated to the base fabric. It is then immersed into water, which has affinity to solvent (DMF) and does not have affinity to PU resins. After the solvent (DMF) is replaced by water, the PU resin congeals gradually and a porous involucra is formed. This congealed resin is also called BASS, which then undergoes further processing, such as printing, embossing, grinding and is shaped into finished products.

Our wet-process PU resin for synthetic leather and wet-process PU resin for microfiber are characterized by their fast clotting, low blocking, and high peeling strength. The filmed wet process PU resin is resistant to water, acid, alkali, heat, abrasion, and aging. It is widely applied in the manufacture of high quality clothing, shoes, basketballs, bags, labels and nubuck leather.

Apart from wet process PU resin, we also offer dry process PU resin, the PU systems for shoe soles, adhesive resins, and more PU resins.